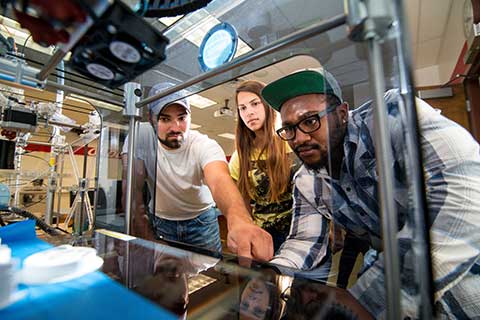

The Manufacturing Engineering Technology degree program covers a broad range of technologies necessary to apply and control manufacturing processes. It includes production methods for industrial and consumer products. The manufacturing engineering technology professional must be able to plan, design and implement the facilities, tools and machines used in production as well as understand the operations process to produce high-quality products at competitive prices.

B.S. Degree in MET (4-Year)

Four-year B.S. degree graduates qualify for jobs related to production, process and productivity improvement, and process design. They also qualify for supervisory and managerial positions in plant engineering.

Graduates of Missouri Western’s manufacturing program have a strong and broad foundation that enables them to perform well in any field in which application of manufacturing principles is required.

Students can choose three paths in the four-year B.S. degree:

The General concentration provides students with the building blocks to continue their education and achieve a bachelor’s degree in Manufacturing Engineering Technology with a concentration in either bio-manufacturing or design and technical graphics.

The Design & Technical Graphics concentration in the Manufacturing Engineering Technology program focuses on the computer applications, especially computer-aided drafting and design, for industries. It is created to meet the business and industrial trend of more and more computer applications in production.

A.A.S. Degree in MET (2-Year)

The Department also offers a two-year A.A.S. in Manufacturing Engineering Technology.

Career opportunities for two-year associate degree graduates of Manufacturing Engineering Technology include entry-level positions with industries engaged in plant design, machine and tool design, robotics and industrial automation, and computer-integrated manufacturing.

Students can choose three paths in the two-year A.A.S. degree:

The General concentration provides students with the building blocks needed to achieve an associate’s degree in Manufacturing Engineering Technology .

The Instrumentation and Automation concentration focuses on hands-on learning in electricity, electronics and computer applications in industry and is designed to meet the workforce needs in the expanding electronics and automation applications field. Career opportunities for two-year associate degree graduates with the Instrumentation and Automation option include entry-level positions with industries engaged in industrial automation, automated production line operation, plant electricity and computer-integrated manufacturing operation and maintenance.

The Precision Machining concentration centers on hands-on learning in Missouri Western’s expanded professional machine tool and CNC labs and prepares workforce ready graduates. Career opportunities for two-year associate degree graduates with the Precision Machining option include entry-level positions with industries engaged in machine and tool design, manufacturing machine operation, CNC operation and troubleshooting/maintenance.